This unit replaces the Anybus AB7650-F Communicator

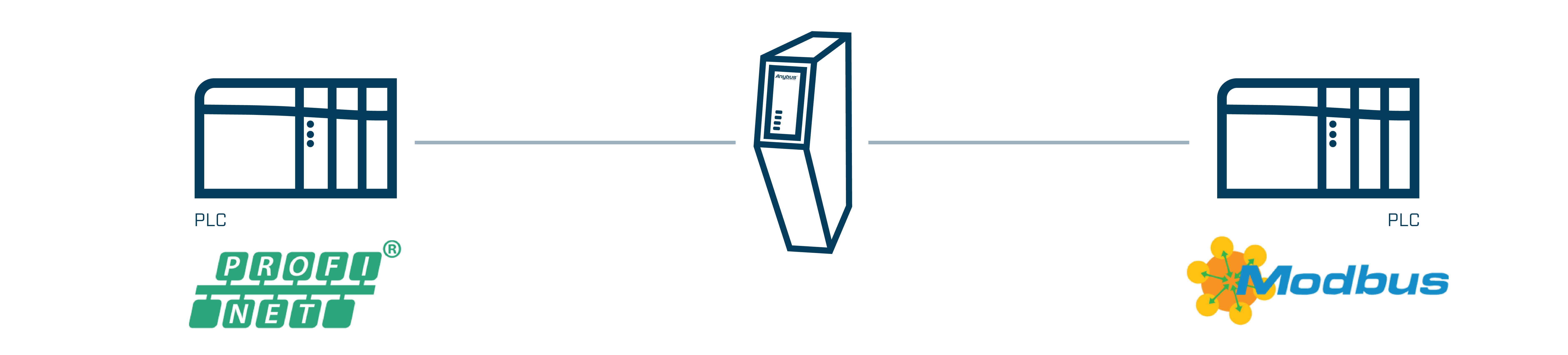

The Anybus Communicator PROFINET IO-Device – Modbus TCP server is an industrial protocol gateway that allows you to seamlessly transfer data between PLC control systems over PROFINET and Modbus TCP networks.

Anybus Communicators are designed to ensure reliable, secure, and high-speed data transfer between different industrial Ethernet and Fieldbus networks. Very easy to install and deploy, the stand-alone gateways enable transparent data exchange between PLCs allowing you to both bridge and integrate legacy equipment into modern high-performance networks with only minimal changes to the software.

Award-winning Anybus NP40 industrial network processor

Anybus Communicators are built using the award-winning and proven Anybus NP40 industrial network processor providing network conformance, high performance, and reliability. When connecting between PLCs on different networks, extremely fast data cycling is enabled with data transfer of up to 1500 bytes in each direction, meeting most current control application needs as well as supporting future demands.

Quick installation is ensured thanks to the intuitive configuration, easy-to-understand documentation, and smart hardware and housing design.

Product Information

Excellent performance

- Instant data transfer – The time it takes to transfer data between two PLCs consists of the cycle time on the first network plus the cycle time on the second network. Internal data transfer in the Communicators is negligible as it’s in line with the natural variation of the network cycle times (jitter).

- Hardware-accelerated endian conversion (byte swap) – The Communicators can change the data representation (endianness) through a hardware-accelerated endian conversion to ensure data is presented correctly in each PLC. You can even convert different parts of the data area in different ways to handle different data types. It has no impact on performance, offloads the PLC of the data conversion task, and simplifies PLC programming.

Easy to Use

- Dedicated ethernet configuration port – no special cables required.

- Intuitive web-based drag and drop configuration interface – no need to install any additional software.

- Forward-facing ports make it easy to connect cables and the slim form factor saves space on the DIN rail.

- Troubleshoot problems with powerful diagnostics including live data monitor, status screen, and support package.

Latest Security Features

- Secure boot functionality to detect tampering with firmware and resist attacks and infection from malware.

- Security switch which locks your configuration and prevents any unauthorised access.

Designed for industrial environments

- Robust compact housing.

- Industrial components are tested and certified according to CE and UL.

- Wide temperate range, -25°C to 70°C.

- DIN-rail mounting to enable installation close to connected devices, reducing the amount of wiring.

- PROFINET IO-Device (slave)

- Transfer up to 1 024 bytes to and from PROFINET (2048 bytes total)

- 1 ms minimum cycle time

- Conformance class B, Real-Time (RT)

- High robustness against network load, Netload Class III

- Dual RJ45 Ethernet ports with 10/100 Mbit full duplex

- Daisy chaining with integrated switch

- Modbus TCP server

- Transfer up to 1 500 bytes to and from Modbus TCP (3 000 bytes total)

- 4 connections

- Function codes 01-06, 15-16, 23, 43/14

- Dual RJ45 Ethernet ports with 10/100 Mbit full duplex

- Daisy chaining with integrated switch

GENERAL

| Dimensions (L x W x H) with serial and power connector | 98 x 27 x 144 mm 3.85 x 1.06 x 5,67 in |

| Weight | 150 grams, 0.33 lb |

| Buttons and switches | Reset button and security switch |

| LEDs | Gateway, Network 1 & Network 2 |

| IP rating | IP20 |

| Housing material | PC ABS, UL 94 VO |

| Mounting | DIN rail (35 * 7,5/15) |

ENVIRONMENT

| Operating temperature | -25 to 70° C, -13 to 158° F |

| Storage temperature | -40 to 85° C, -40 to 185° F |

| Relative humidity | 0-95% non-condensing |

| Installation altitude | Up to 2 000 m |

POWER

| Input voltage | 12 – 30 VDC |

| Current consumption | Typical: 160 mA @ 24V Max: 400 mA @ 12V |

| Power connector | 3-pin plug with screw terminal |

| Protection | Reverse voltage protection and short circuit protection |

ETHERNET PORTS

| Ports | 2+2 x Ethernet |

| Isolation | Galvanic isolation |

| Bitrate | 10/100 Mbit full duplex |

| Connector | RJ45 |

| Switch. | A dual port cut-through switch |

PROFINET

| Mode | PROFINET IO-Device (slave) |

| Class | A, B |

| Communication channels | Real-Time Channel (RT) |

| Input data size | 1 024 bytes |

| Output data size | 1 024 bytes |

| Minimum cycle time | 1 ms |

| Max number of connections | 1 IO Controller Application Relationship + 2 Device Access Application Relationships |

| Netload class | Class III |

| I&M records | Manufacturer data (I&M0), Tag information (I&M1), Date/Time (I&M2), Description (I&M3) |

| SNMP | Available |

| GSDML File | Available |

| Certification | Pending |

MODBUS TCP

| Mode | Server |

| Max number of connections | 4 |

| Input data size | 1 500 bytes |

| Output data size | 1 500 bytes |

CERTIFICATIONS AND STANDARDS

| UL | CULUSfile number E214107 |

| CE | 2014/30/EU |

| KC | R-R-ABJ-Communicator |

| EMC | EN 61000-6-2 EN 61000-4-2 EN 61000-4-3 EN 61000-4-4 EN 61000-4-5 EN 61000-4-6 EN 61000-6-4 EN 55032 |

| Environment | IEC 60068-2-1 Ab IEC 60068-2-2 Bb IEC 60068-2-1 Ab IEC 60068-2-2 Bb IEC 60068-2-14 Nb IEC 60068-2-30 Db IEC 60068-2-78 Cab IEC 60068-2-78 Cab |

| Vibration and shock | IEC 60068-2-27 IEC 60068-2-6 |

| Waste certification | WEE |

CONFIGURATION

| Configuration software | Web-based configuration |

| Configuration ports | Dedicated 10/100 Mbit RJ45 Ethernet configuration port and Ethernet ports |

SECURITY

| Secure boot | Ensures software authenticity |

| Security switch | Physical switch that enables/disables access to the web-based configuration interface |

PRODUCT PACKAGING

| Content | Gateway, power connector, start-up guide, compliance information sheet |

| Box material | Cardboard |

MEAN TIME BETWEEN FAILURE

| MTBF | > 1500000 h, Telcordia Method I Case 3 at 30° C |

Book your product

We are fully committed to providing our customers with the very best products and customer service. We believe in going the extra mile to ensure that each customer is satisfied with our products and solutions. We have the experience and the reputation in the field to deliver the products customers need to expedite their projects and assure quality every step of the way.