Specifically designed to allow bidirectional control and monitoring of all parameters and functionalities of your building automation projects

This bidirectional gateway provides a straightforward and fast integration thanks to its unique onboard features. The BTL mark ensures 100% compatibility and, at the same time, guarantees seamless integration with any BACnet device.

The configuration is carried out using the Intesis MAPS software. This one allows you to define your own settings for the device. Also, it will be able to download all the available project templates or to import any created/exported project template on your computer.

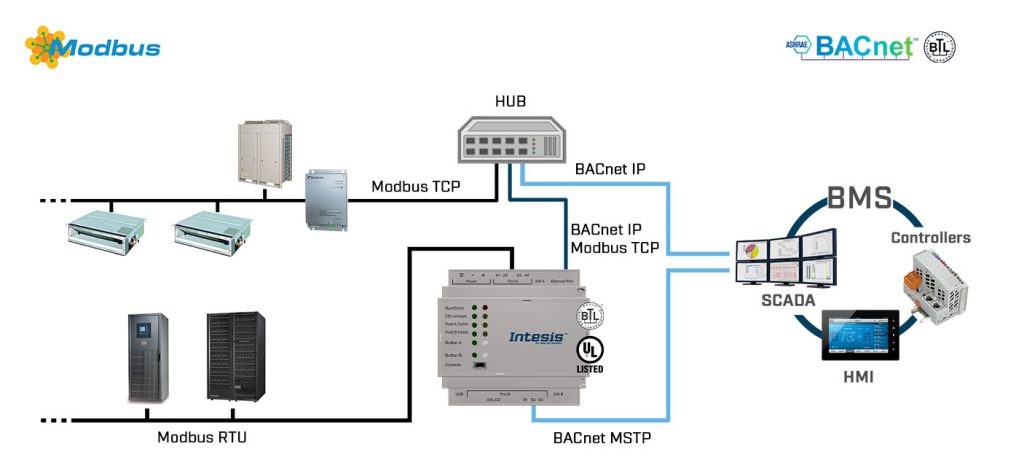

Integrate any Modbus RTU or TCP server device, or both at the same time, with a BACnet BMS or any BACnet IP or BACnet MS/TP controller. The aim of this integration is to make accessible Modbus system signals and resources from a BACnet based control system or device as if it was a part of the own BACnet system and vice-versa.

Modbus Protocol Translators

Bring connectivity to your Modbus management system thanks to Intesis Modbus solutions. Connect BACnet, KNX, LonWorks, DALI, or M-BUS devices to Modbus systems and extend your building management system capabilities.

Intesis Modbus can act as a Modbus RTU device, Modbus TCP device, or both.

On the Modbus server versions, the gateway provides server functionality to the BMS or Modbus controller over Modbus TCP through the Ethernet port and over Modbus RTU through the serial port (EIA485 or EIA232).

On the Modbus client versions, the gateway provides client functionality to control Modbus TCP server devices through Ethernet and Modbus RTU devices through the serial port. In such cases, control and monitoring of Modbus devices from BACnet and KNX BMS controllers is possible.

- Great integration flexibility thanks to KNX TP, RS485, Ethernet, DALI, or M-Bus interfaces.

- Scaled licenses per number of datapoints help to find the right gateway version for your project.

- Modbus advanced functionalities to improve internal and external protocol communications.

- Modbus template repository with most common Modbus devices and template generator to create your own template devices.

Modbus TCP & RTU

All Modbus gateways can communicate with Modbus TCP and RTU networks at the same time.

Most I/O Modbus functions supported

Use any I/O function code of the wide range supported by Modbus gateways (1x, 2x, 3x, 4x, 5x, 6x, 15x, and 16x).

Multiple data formats

Configure the data length (1, 16, 32, 48, or 64 bits), format (unsigned, signed, float, and bitfield), and byte order (big or little-endian).

Polling groups

Improve Modbus communications grouping register requests per device, asking multiple registers in a single request.

BACnet Protocol Translators

Our BACnet solutions have been specially designed to allow supervision and bidirectional control of systems and equipment talking BACnet, DALI, KNX, LonWorks, M-Bus, and Modbus protocols.

On the BACnet server versions, the gateway provides server functionality to the BMS or BACnet controller over BACnet/IP through the Ethernet port and over BACnet MS/TP through the serial port.

On the BACnet client versions, the gateway provides client functionality to control BACnet IP server devices through Ethernet and BACnet MSTP devices through the serial port. In such cases, control and monitoring of BACnet devices from ASCII, KNX, and Modbus BMS controllers is possible.

- Great integration flexibility thanks to KNX TP, LonWorks, RS485, Ethernet, DALI, or M-Bus interfaces.

- Scaled licenses per number of datapoints help to find the right gateway version for your project.

- Conforms to BACnet revision 14, B-AAC Profile.

- Supports BI, BO, AI, AO, Device, BV, AV, MI, MO, MV, NC, Schedule, and Calendar BACnet objects.

- Supports subscription requests (COV).

- BTL certified.

BACnet IP and MSTP

The device can communicate through Ethernet or serial ports with BACnet IP or BACnet MSTP networks.

BBMD and foreign Devices

BACnet devices can work in complex BACnet/IP networks, providing the ability to communicate between subnets or/and through routers.

Advanced features

All Intesis BACnet Servers allow hosting notification class, calendar, schedule, and trend log objects as well as support for subscription requests (COV).

BTL certified

It provides an assurance that products have been independently tested and have passed industry-standard BACnet testing.

Product Information

- UL Certified

- BTL Certified

- Support for BACnet IP Client and MSTP Master

- BACnet Advanced features available (Trend logs, Calendars, etc.)

- Support for 2 independent RTU ports for integration into BACnet IP < NEW!

- Up to 5 Modbus TCP nodes/devices

- Up to 32 Modbus devices per RTU node (without repeater) and up to 255 in total

- Possibility to generate/download templates of your Modbus products

- Easy integration & updates with Intesis MAPS

ORDER CODES:

| INBACMBM1000000 | Modbus TCP & RTU Master to BACnet IP & MS/TP Server Gateway – 100 points |

| INBACMBM2500000 | Modbus TCP & RTU Master to BACnet IP & MS/TP Server Gateway – 250 points |

| INBACMBM6000000 | Modbus TCP & RTU Master to BACnet IP & MS/TP Server Gateway – 600 points |

| INBACMBM1K20000 | Modbus TCP & RTU Master to BACnet IP & MS/TP Server Gateway – 1200 points |

| INBACMBM3K00000 | Modbus TCP & RTU Master to BACnet IP & MS/TP Server Gateway – 3000 points |

- Intesis Gateway.

- Installation Manual.

- USB Configuration cable.

- (Power supply not included).

- Warranty: 36 months.

Book your product

We are fully committed to providing our customers with the very best products and customer service. We believe in going the extra mile to ensure that each customer is satisfied with our products and solutions. We have the experience and the reputation in the field to deliver the products customers need to expedite their projects and assure quality every step of the way.